A heat exchanger is a heat transfer device that exchanges heat between two or more..

Pioneer Radiator heat exchangers have many applications and are used in refineries, petrochemical, chemical, fertilizer and pharmaceutical, air-conditioning & refrigeration plant, heat treatment shops, marine engines & gear boxes, fluid couplings in power plants, machine tools, diesel engine generating sets, compressors, air separation plants, power plant installations, transformers, hydraulic power packs, food processing, vegetable oil refining & sugar industry

Introduction

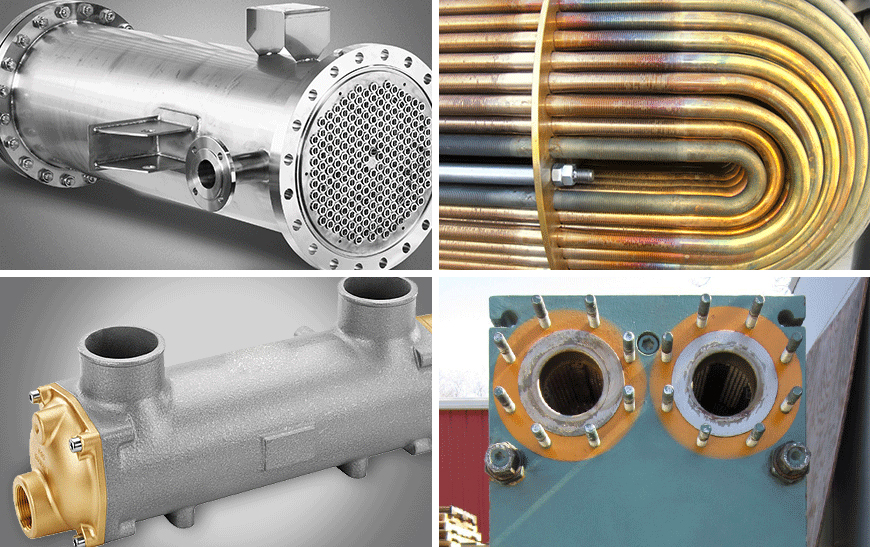

Pioneer Radiator is a company professionally managed by a team of engineers specialized in design & manufacture of shell & tube heat exchangers. We are specialists & offer nothing but first quality product with full complement of services to match. The company has manufacturing capability of a very wide range of heat exchangers, weights ranging from 10Kg to 250 tones and in a variety of materials such as copper, brass carbon steels, stainless steel 304, 310, 316, 316L, copper alloys such as cupro nickel, admiralty & aluminum brass, nickel, aluminium, bronze and many other materials.

Extended surface heat exchanger :

Customized design for centrifugal compressor intercoolers & after coolers. They are capable of cooling large volumes of air or nitrogen at minimal pressure loss, close temperature approach to cooling water is possible. It is a removable bundle design with multi-pass tube side, internal demister mounting for wet air condensation is most compact and energy efficient solution for the gas cooling application.

High pressure shell & tube heat exchanger :

When the design pressure of gas is more than 50 bar, then it is recommended to design the heat exchanger with gas on tube side & water on shell side. It is a removable tube bundle with an outside packed floating tube sheet design used when gasket malfunctioning should be detectable.

We are also manufacturing high pressure heat exchangers having a design pressure of 380 bar for our esteemed customer. These heat exchangers are being used for the marine application.

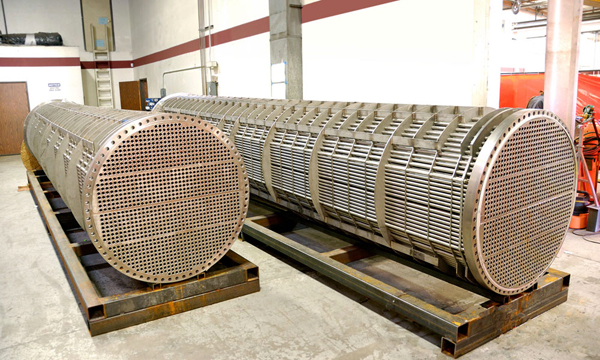

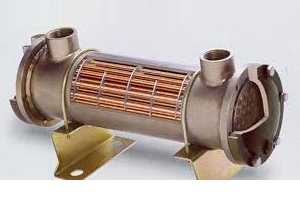

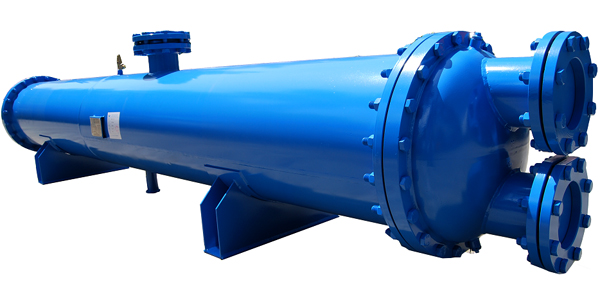

Shell & tube heat exchanger :

Shell & Tube heat exchangers are most commonly used in almost all industries like refineries, chemical plants, fertilizer plants, genset units, oil & gas and shipping. Typical use of heat exchanger is to cool or heat the fluids or gases.

We manufacture almost all TEMA shell, tube heat exchangers and also manufacture duplex coolers, shell in series and shells in parallel type heat exchangers.

Compact heat exchanger :

These are compact shell & tube type with plate fin design used for general purpose oil coolers. They are designed for wide variety of industrial application and are mainly used as lubrication oil coolers. These heat exchangers are also available in duplex type and are proprietary special designs as per good engineering practice.

Pressure vessels :

Pressure vessels are most commonly used in almost all industries like refineries, chemical plants and fertilizer plants.

These pressure vessels are mainly used as gas storage, water storage, air receivers, separators, fuel tank and buffer vessels

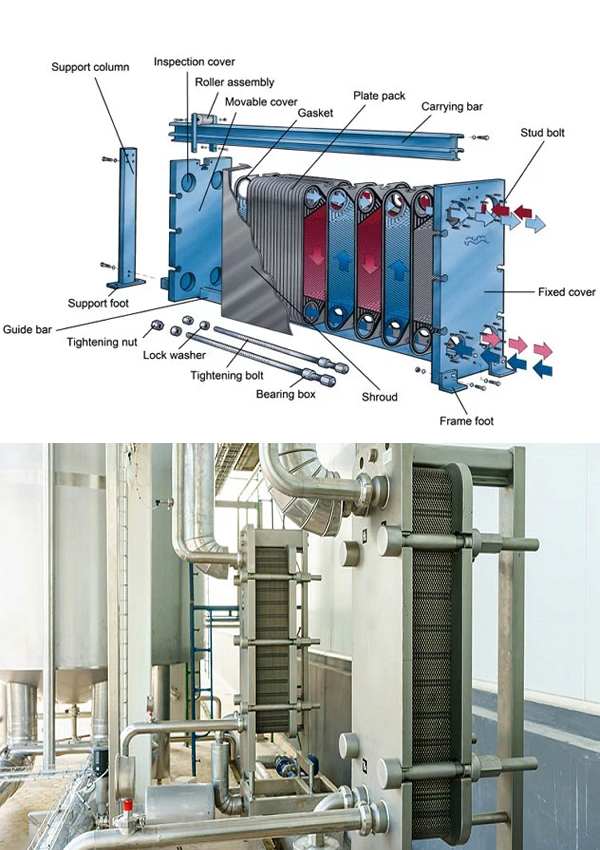

Plate type heat exchanger :

The plate type heat exchanger is a pack of thin plates arranged in a frame, so that the space between each alternate plate is open to the same fluid. The plates are corrugated, which gives them strength and helps promote turbulent flow. The plates may be arranged in a series of passes to achieve the correct liquid velocity and an acceptable pressure drop.

- Carrying beam: The top component placed between the fixed plate and supporting column upon which the PHE plates and the pressure plates are suspended.

- Fixed plate: The basic component of the PHE frame. The fixed plate is an unmovable frame plate. Normally, the pipes are connected to this component.

- Support column: A fixed component of a PHE frame to which the carrying beam and the guiding bar are fixed.

- Pressure plate: A moveable frame plate suspended at the carrying beam of the PHE frame. This frame compressed the PHE plates.

- Guiding bar: Component that guides the PHE plates and the pressure plate at the bottom.

- Tightening unit: The frame component for compressing the PHE plate pack. It consists of tightening bolts, tightening nuts and washers.

- PHE Plates and gasket: The plate pack is assembled between a stationary frame plate and a pressure plate and compressed by tightening bolts fitted between these two plates. The channel plates and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar.

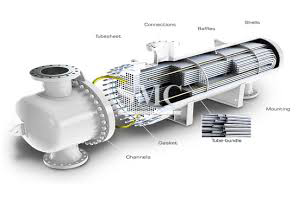

Tube bundle heat exchanger

An intermediate tube bottom, having insert tubes arranged concentrically in the tubes, is located in the inlet chamber, with these insert tubes projecting out on both sides from the tubes and forming annular spaces therewith. The heat exchanger has an inlet tube bottom and an outlet tube bottom, in which are fastened the ends of tubes which connect the bottoms and through which the medium of high inlet temperature flows.

A tube-bundle heat exchanger for cooling a medium having a high inlet temperature. Toward the inlet chamber, the annular spaces open into an intermediate chamber limited by the inlet tube bottom and the intermediate tube bottom; in the opposite direction, the annular spaces open into a deflecting or reversing chamber sealingly covering the insert tubes.